1. State the characteristic features of synchronous motor.

Ans: a. the motor is not inherently self starting

b. The speed of operation is always in synchronous with the supply frequency irrespective of load conditions

c. The motor is capable of operating at any power factor.

2. In what way synchronous motor is different from other motors?

All dc and ac motors work on the same principle. Synchronous motor operates due to magnetic locking taking place between stator and rotor magnetic fields.

3. Name any two methods of starting a synchronous motors

• By an extra 3 phase cage induction motor

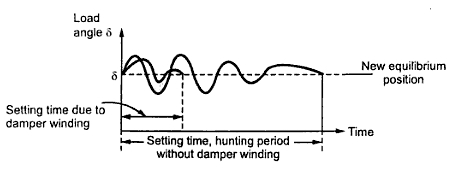

• By providing damper winding in pole phases

• By operating the pilot excitor as a dc motor

4. What is the effect on speed if the load is increased on a 3 phase synchronous motor?

The speed of operation remains constant from no load to maximum load in the motor operating at constant frequency bus bars.

5. Why a synchronous motor is a constant speed motor

Synchronous motor work on the principle of force developed due to the magnetic attraction established between the rotating magnetic field and the main pole feed. Since the speed of rotating magnetic field is directly proportional to frequency the motor operates at constant speed.

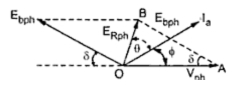

6. What is the phasor relation between induced emf and terminal voltage of a 3 phase synchronous motor?The rotating magnetic field is initially established by the prime source of supply V. The main field then causes an emf e to get induced in the 3 phase winding. Hence when the machine operates as a synchronous motor the emf phasor always lags the terminal voltage phasor by the load1torque angle .

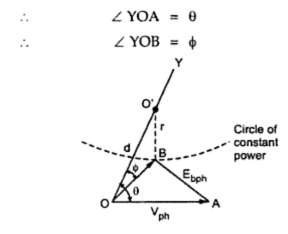

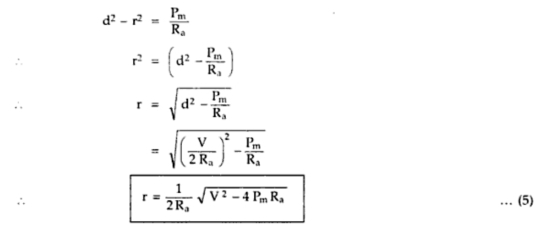

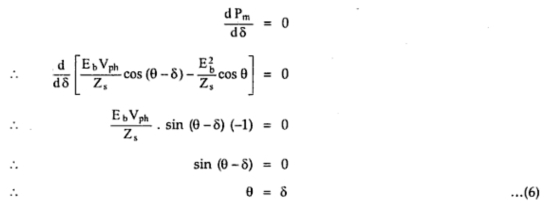

7. At what load angle is power developed in a synchronous motor becomes its maximum value ?

When its load angle is equal to the impedance angle .

8. What are V and inverted V curves of synchronous motor ?

The variation of magnitude of line current with respect to the field current is called V curve . The variation of power factor with respect to the field current is called inverted V curve.

9. What happens when the field current of a synchronous motor is increased beyond the normal value at constant input?

Increase in emf causes the motor to have reactive current in the leading direction. The additional leading reactive current causes the magnitude of line current, accompanied by the decrease in power factor.

10.Distinguish between synchronous phase modifier and synchronous condenser

A synchronous motor used to change the power factor or power factor in the supply lines is called synchronous phase modifier.

A synchronous motor operated at no load with over excitation condition to draw large leading reactive current and power is called a synchronous condenser

Ans: a. the motor is not inherently self starting

b. The speed of operation is always in synchronous with the supply frequency irrespective of load conditions

c. The motor is capable of operating at any power factor.

2. In what way synchronous motor is different from other motors?

All dc and ac motors work on the same principle. Synchronous motor operates due to magnetic locking taking place between stator and rotor magnetic fields.

3. Name any two methods of starting a synchronous motors

• By an extra 3 phase cage induction motor

• By providing damper winding in pole phases

• By operating the pilot excitor as a dc motor

4. What is the effect on speed if the load is increased on a 3 phase synchronous motor?

The speed of operation remains constant from no load to maximum load in the motor operating at constant frequency bus bars.

5. Why a synchronous motor is a constant speed motor

Synchronous motor work on the principle of force developed due to the magnetic attraction established between the rotating magnetic field and the main pole feed. Since the speed of rotating magnetic field is directly proportional to frequency the motor operates at constant speed.

6. What is the phasor relation between induced emf and terminal voltage of a 3 phase synchronous motor?The rotating magnetic field is initially established by the prime source of supply V. The main field then causes an emf e to get induced in the 3 phase winding. Hence when the machine operates as a synchronous motor the emf phasor always lags the terminal voltage phasor by the load1torque angle .

7. At what load angle is power developed in a synchronous motor becomes its maximum value ?

When its load angle is equal to the impedance angle .

8. What are V and inverted V curves of synchronous motor ?

The variation of magnitude of line current with respect to the field current is called V curve . The variation of power factor with respect to the field current is called inverted V curve.

9. What happens when the field current of a synchronous motor is increased beyond the normal value at constant input?

Increase in emf causes the motor to have reactive current in the leading direction. The additional leading reactive current causes the magnitude of line current, accompanied by the decrease in power factor.

10.Distinguish between synchronous phase modifier and synchronous condenser

A synchronous motor used to change the power factor or power factor in the supply lines is called synchronous phase modifier.

A synchronous motor operated at no load with over excitation condition to draw large leading reactive current and power is called a synchronous condenser